Products

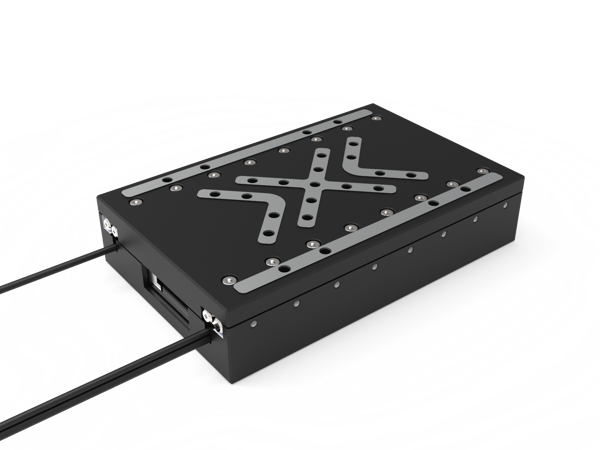

E-UMS130-X(High precision Linear Motorized Translation Stage)

E-UMS130-X series adopts high-precision cross roller guide rail with anti-creep function, cooperates with linear motor and high-resolution grating scale, and has the advantages of small size, large load and low noise. The anti-creep cross roller guideway is especially suitable for applications requiring fine-step travel, with.

The high-performance drive control system can stably step out at a step size of 10nm, which is an important performance that is difficult to guarantee for ordinary linear guide rail linear motor platforms. Therefore, the UMS130-X series is especially suitable for high-precision positioning, detection, exposure and micro-processing application scenarios.

● Non-contact direct drive motor, ultra-high precision and excellent dynamic performance;

● Ironless motor, the speed fluctuation is less than one thousandth (combined with the specified type of drive, laboratory environment test data) ;

● Quiet and anti-creep guide rails to ensure micro-step control;

● Long service life, maintenance-free use for a long time;

Highly accurate position measuring with incremental linear encoder

There is a choice of cost-efficient incremental encoders, metrology-class Incremental encoders and absolute measuring encoders (no referencing on power up required). Since the linear position of the stage is measured directly at the moving platform against the stationary base, without contact (direct metrology), backlash, mechanical play, or deformation in the drive train as common with motor / leadscrew combinations have no influence on position accuracy.

Crossed roller guide

With crossed roller guides, the point contact of the balls in ball guides is replaced by line contact of the hardened rollers. Consequently, they are considerably stiffer and need less preload, which reduces friction and allows smoother running. Crossed roller guides are also distinguished by high guiding accuracy and load capacity. Force-guided rolling element cages prevent cage creep.

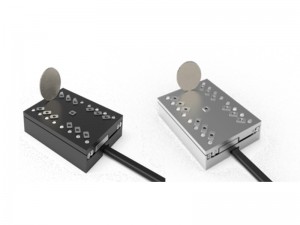

Multi-Axis Stage Combinations: XY and XYZ

2-axis and 3-axis stage combinations are feasible. XY tables can be built by stacking two single-axis stages, while a custom Z-axis with weight force compensation can be used for XYZ translation stage combinations. Another Z-axis option is the very compact UMS130-X vertical linear stage with user-adjustable integrated magnetic counterbalance.

Application fields

Industry and research. Metrology. Photonics and precision scanning in semiconductor or flat panel display manufacturing.

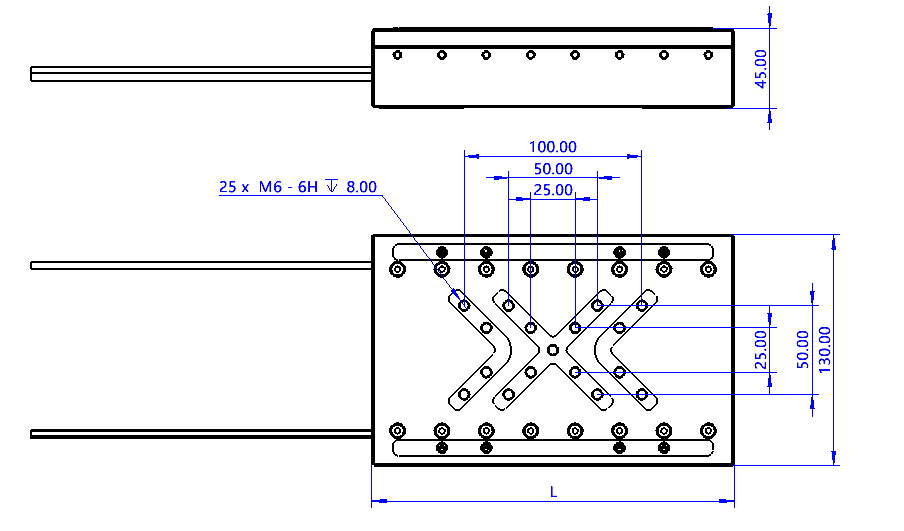

| Specification | UMS130-60X | -110X | -160X |

| Motor type | Three-phase ironless motor | ||

| Encoder type | Incremental encoder 0.1um (optional up to 1nm encoder, absolute optional) | ||

| Motor thrust | Rated 40N Peak 90N | ||

| Acceleration (no load) | 3G | 2.5G | 2G |

| Position limitation type | Mechanical, photoelectric, software (triple limit protection) | ||

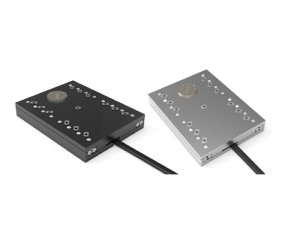

| Material | Aluminum alloy 6061-T6(Optional stainless steel) | ||

| Travel range mm | 60 | 110 | 160 |

| Accuracy um | ±3um(Calibration ±0.5um) | ||

| Repeatability Accuracy um | ±0.1um(±50nm corresponds to grating above 5nm) | ||

| Max Speed mm/s | 300mm/s | ||

| Max load capacity kg | 6 | 8 | 12 |

1) What is the MOQ?

A: MOQ is 1 pcs.

Sample is available for customer to check the quality before bulk order.

2) Do you accept OEM?

A: Yes, OEM and ODM is warmly welcomed.

It is our company’s strength, we can customize the LCD monitor so that can fully meet customers’ requirements.

3) What payment methods does your company accept?

A: T/T, Western Union, Paypal and L/C.

4) What’s the delivery time?

A: Sample: 2-7 working days. bulk order 7-25 working days.

For customized products, delivery time is negotiable.

We will try our best to meet your delivery time.